HeatShrink Wire Markers & Cable Labels – Product Overview

HeatShrink Wire Markers & Cable Labels are designed to simplify cable identification and make wiring projects easier and safer. They are made to meet the high standards of industrial, commercial, and military applications. These markers are durable, flame-retardant, and provide clear, permanent labeling for wires, cables, and cores. Whether you are managing electrical panels, communications wiring, or industrial systems, these markers ensure precise identification and long-lasting performance.

What are heat shrink tubing labels?

Heat shrink tubing labels are specialized sleeves that shrink when heat is applied, tightly wrapping around wires or cables. They provide permanent identification, helping reduce wiring errors and improving safety. Our markers can be printed using thermal transfer printers or purchased pre-printed for convenience. They are ideal for electricians, engineers, and industrial users in the UK.

How do cable markers work?

Cable markers are applied over wires or cable cores and then heated to shrink around the surface. This shrink-wrap effect ensures the labels stay in place, resist abrasion, and remain legible even in harsh conditions. BKLD’s heat shrink cable markers come in ladder format for easy handling and printing, making wire identification quick and efficient.

What materials are used in heat shrink markers?

Our markers are made from cross-linked polyolefin material. This material is flame-retardant, self-extinguishing, and highly durable. It withstands extreme temperatures, cleaning solvents, industrial fluids, and military fuels. The markers are suitable for aerospace, defense, and commercial wiring systems. Our heat shrink wire labels are designed to last, even in the most demanding environments.

What sizes and colors are available?

Our heat shrink markers come in multiple diameters, ranging from 2.4mm to 38.1mm unshrunk, with sleeve lengths that accommodate different cable sizes and character requirements. Colors include white, yellow, red, green, blue, violet, black, orange, and grey. This variety makes it easy to organize and identify wires and cables at a glance.

Are there pre-printed heat shrink wire labels?

Yes. We offer pre-printed heat shrink wire labels for customers who need immediate use. Pre-printed labels save time and ensure consistency across large wiring projects. Alternatively, customers can use a thermal transfer printer to print custom messages directly onto blank markers. This flexibility is ideal for industrial or commercial wiring projects in the UK.

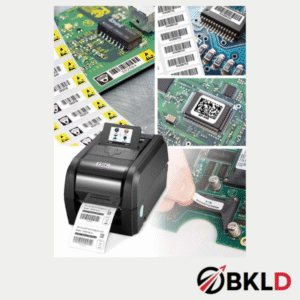

How to print on heat shrink cable markers?

To print on heat shrink cable markers, use a thermal transfer printer. The printer heats the ribbon, transferring ink directly onto the marker. This produces sharp, long-lasting text that resists fading, abrasion, and chemical exposure. Printing markers in ladder format makes the process efficient, reducing installation time.

What is the best heat source for heat shrink?

The ideal heat source for applying heat shrink labels is a heat gun. Heat guns provide even heat distribution, ensuring the markers shrink uniformly without damaging the cable or marker. They are safe, reliable, and easy to use for professional or DIY wiring tasks.

What are CCUV clear protective sleeves?

CCUV sleeves, like the TMS-CCUV clear protective sleeves, are designed for UV protection and cable identification. They offer crystal-clear visibility while safeguarding the label against environmental damage. These sleeves are perfect for outdoor or industrial applications where durability and readability are essential.

What are the applications of heat shrink wire markers?

BKLD heat shrink wire markers are suitable for multiple industries:

-

Electrical panels

-

Communications systems

-

Wire assemblies

-

Industrial automation

-

Aerospace and defense wiring

-

Commercial wiring installations

These markers are CSA Certified and UL Recognized, ensuring compliance with industry standards. They resist abrasion, cleaning solvents, and industrial fluids while maintaining clear identification.

What are the advantages of heat shrink labels for cables?

Heat shrink labels offer numerous advantages:

-

Permanent, reliable identification

-

Resistance to chemicals, oils, and abrasion

-

Flame-retardant and self-extinguishing material

-

Easy to print and install

-

Wide variety of sizes and colors

-

Suitable for commercial and industrial wiring

BKLD’s markers are supplied in ladder format for easy handling and kitting. You can hand-write additional information on the side carrier if needed.

How can I order custom heat shrink cable labels?

We provide custom printed core ident markers to meet unique project requirements. You can choose pre-printed options or order software and printers to print labels on-site directly from Excel spreadsheets. Customization ensures that your wiring labels match project specifications, cable sizes, and color codes.

Are heat shrink markers durable?

Yes. BKLD heat shrink markers are designed for durability. They remain legible under harsh conditions, including abrasion, chemical exposure, extreme temperatures, and military-grade fluids. Once printed and shrunk, the labels are permanent, reducing maintenance and errors in cable management.

What certifications do these wire labels have?

HeatShrink Wire Markers & Cable Labels are CSA Certified and UL Recognized. These certifications confirm that the markers meet high safety and performance standards for electrical and industrial applications. Customers can trust the product for commercial, industrial, and military wiring projects.

Why choose BKLD heat shrink wire markers?

BKLD is a trusted brand for wire labeling and identification solutions. Their heat shrink wire markers offer unmatched durability, clarity, and compliance. Using BKLD products ensures accurate wiring, improved safety, and time-saving installation processes. With a variety of sizes, colors, and pre-printed or printable options, BKLD markers provide reliable solutions for all cable labeling needs.

Where to buy HeatShrink Wire Markers & Cable Labels in the UK?

You can buy HeatShrink Wire Markers & Cable Labels directly from us at BKLD. We supply high-quality markers suitable for industrial, commercial, and military wiring projects. Whether you need pre-printed markers, custom labels, or thermal transfer printing kits, we provide fast delivery and expert support across the UK. Contact us today to get the right markers for your project and ensure professional, long-lasting wire identification.

Reviews

There are no reviews yet.